Search

Precautions when using ceramic cutting machine

- Categories:Ceramics cutting machine News

- Time of issue:2022-09-07 13:35

- Views:

(Summary description)1. Always disconnect the power supply during maintenance and repairs at all times. 2. The tool used by the ceramic cutting machine is a diamond saw blade, which cannot cut metal materials and cannot be cut in a random curve.

Precautions when using ceramic cutting machine

- Categories:Ceramics cutting machine News

- Time of issue:2022-09-07 13:35

- Views:

1. Always disconnect the power supply during maintenance and repairs at all times.

2. The tool used by the ceramic cutting machine is a diamond saw blade, which cannot cut metal materials and cannot be cut in a random curve.

3. When replacing a new blade, check the blade for cracks, nicks and bends, and test it after installation.

4. Using a dull saw blade will cause the motor to not work properly, and a new blade should be replaced on time, or use a refractory brick to cut and sharpen the blade.

5. The motor of the cutting machine is in the S6 working system. When the motor automatically stops during use, it is the automatic protection of the motor. Please stop it for ten minutes, and then turn on the switch, and the motor can work again.

6. Pay attention to the grounding of the power supply, and children should not turn it on.

7. Regularly check the loose parts such as machine safety guards.

8. Replace the saw blade regularly. A dull saw blade can damage the motor and affect the cutting quality and efficiency of the machine.

9. Be sure to avoid prolonged exposure of wires and electrical components to water or moisture. Keep all parts dry and free from moisture.

10. After each use, you need to drain the water in the basin and clean the basin at the same time. Since it is working with water, all parts of the machine should also be wiped dry to prevent rusting.

11. After each use, clean the water pump pipeline and filter cotton with clean water to ensure that the pipeline is unblocked. If the water pump fails to discharge water normally, please contact the supplier for replacement immediately. Waterless cutting is strictly prohibited for this type of machine.

12. Periodically inspect the fasteners of each part of the machine to ensure they are properly tightened.

Hot news

In a significant development for the manufacturing industry, a new German Type Hose Clamp Automatic Machine is set to revolutionize efficiency and precision in hose clamp production, offering a seamless and streamlined solution for various applications.

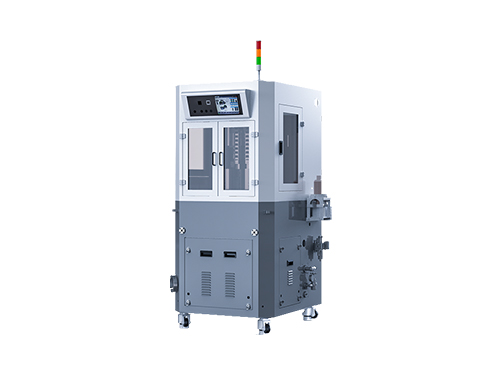

In the realm of precision manufacturing, a groundbreaking innovation has emerged with the introduction of the High Precision Ceramic Cutting Machine. This cutting-edge machine is set to revolutionize the industry by offering unparalleled accuracy, efficiency, and versatility in ceramic material cutting.

Scan the code to contact us

Scan the code to contact us