Search

Daily maintenance method of ceramic cutting machine

- Categories:Ceramics cutting machine News

- Time of issue:2022-09-09 15:16

- Views:

(Summary description) Make sure that the tile pipe is full of circulating water before the machine works. The water quality and temperature of the circulating water directly affect the service life of the tile pipe.

Daily maintenance method of ceramic cutting machine

- Categories:Ceramics cutting machine News

- Time of issue:2022-09-09 15:16

- Views:

1. Replacement of circulating water and cleaning of water tank:

(1) Make sure that the tile pipe is full of circulating water before the machine works. The water quality and temperature of the circulating water directly affect the service life of the tile pipe.

(2) Therefore, the circulating water should be replaced regularly and the water tank should be cleaned. It is recommended to do it once a week.

2. Fan cleaning:

(1) The long-term use of the fan in the machine will cause a lot of solid dust to accumulate in the fan, which will make the fan generate a lot of noise, and is not conducive to exhaust and odor removal.

(2) When the suction of the fan is insufficient and the smoke exhaust is not smooth, the fan should be cleaned.

3. Lens cleaning:

(1) There will be some reflectors and focusing mirrors on the machine.

(2) The tiles are reflected and focused by these lenses and emitted from the tile head.

(3) The lens is easily stained with dust or other pollutants, resulting in the loss of tiles or damage to the lens.

(4) So clean the lens every day.

4. Pay attention to:

(1) The lens should be wiped gently without damaging the surface coating;

(2) The wiping process should be handled with care to prevent falling;

(3) Be sure to keep the concave side down when installing the focusing lens.

Hot news

In a significant development for the manufacturing industry, a new German Type Hose Clamp Automatic Machine is set to revolutionize efficiency and precision in hose clamp production, offering a seamless and streamlined solution for various applications.

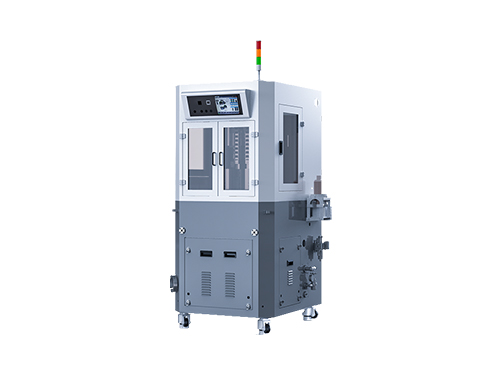

In the realm of precision manufacturing, a groundbreaking innovation has emerged with the introduction of the High Precision Ceramic Cutting Machine. This cutting-edge machine is set to revolutionize the industry by offering unparalleled accuracy, efficiency, and versatility in ceramic material cutting.

Scan the code to contact us

Scan the code to contact us