Search

How to maintain the motor of the grinding and polishing machine

- Categories:Polishing Machine

- Time of issue:2022-08-22 13:56

- Views:

(Summary description)It is mainly used for grinding high-precision planes, inner and outer cylindrical surfaces, conical surfaces, and other workpieces whose machining surfaces are flat surfaces.

How to maintain the motor of the grinding and polishing machine

- Categories:Polishing Machine

- Time of issue:2022-08-22 13:56

- Views:

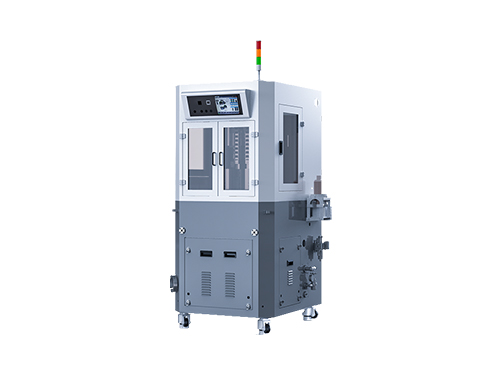

A surface grinder is a grinder that grinds the surface of a workpiece with a grinder coated or embedded with abrasives. It is mainly used for grinding high-precision planes, inner and outer cylindrical surfaces, conical surfaces, and other workpieces whose machining surfaces are flat surfaces.

1. The operating voltage of the motor of the plane grinder is 380V, and it is necessary to ensure that it is used under normal voltage.

2. The frequency of use of the motor of the plane grinder is 50HZ and cannot be used over 50HZ.

3. The current intensity of the motor does not exceed 15A. If it is found to be abnormal, it should be stopped and checked in time.

4. After the switch of the plane grinder motor is started, if it is found that the motor has no starting response in an instant, it should be stopped immediately for inspection, and it can be used normally after the fault is eliminated.

5. If it is found that the motor has dry noise or high temperature (above 80 ℃), it should be stopped immediately for inspection, and it can be used normally only after checking and eliminating the fault.

Hot news

In a significant development for the manufacturing industry, a new German Type Hose Clamp Automatic Machine is set to revolutionize efficiency and precision in hose clamp production, offering a seamless and streamlined solution for various applications.

In the realm of precision manufacturing, a groundbreaking innovation has emerged with the introduction of the High Precision Ceramic Cutting Machine. This cutting-edge machine is set to revolutionize the industry by offering unparalleled accuracy, efficiency, and versatility in ceramic material cutting.

Scan the code to contact us

Scan the code to contact us